Michael Nagel

Well-known member

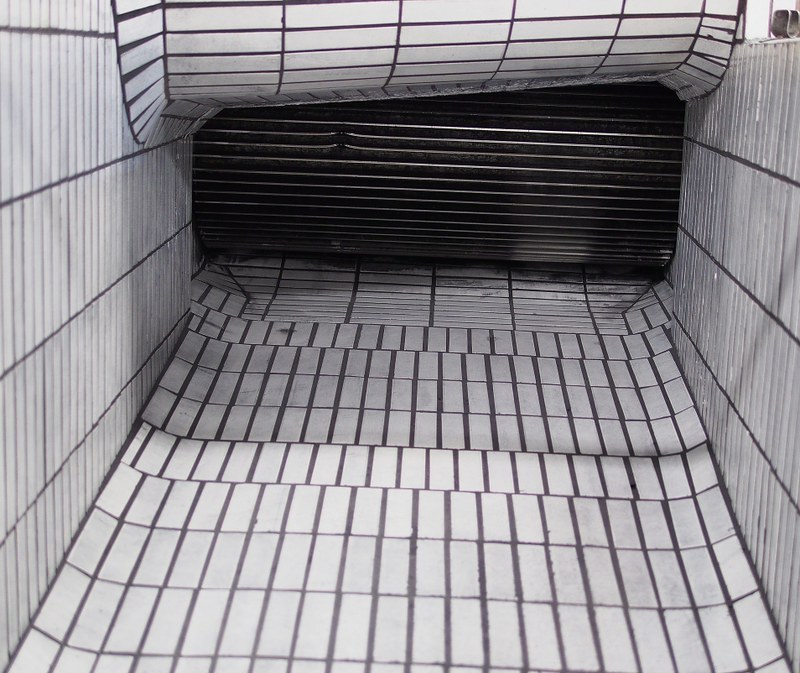

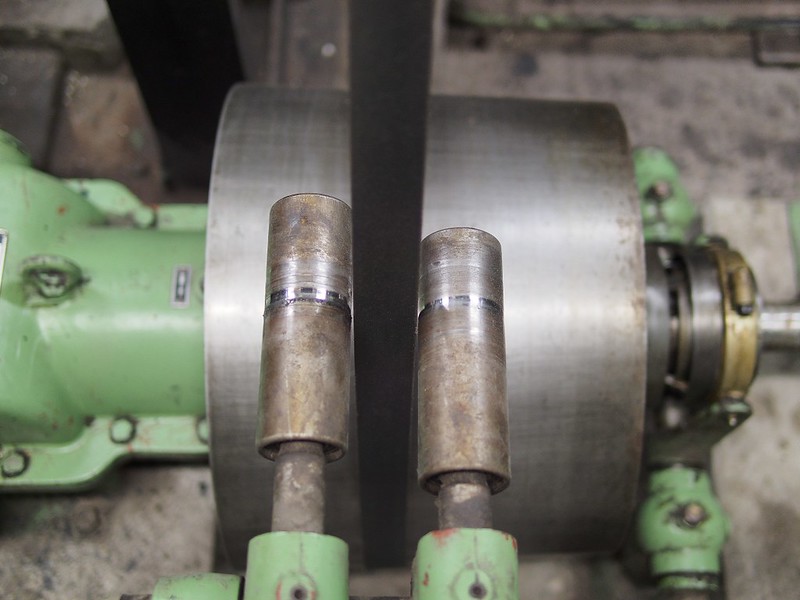

Yesterday I had the occasion to visit a paper factory specialized in high quality paper. There are two machines, the older one was installed more than 100 years ago and is still in use. They are also making hand-made paper.

Four impressions beside the main subject:

More on the factory here.

Best regards,

Michael

Four impressions beside the main subject:

More on the factory here.

Best regards,

Michael