Doug Kerr

Well-known member

It is fairly common here in Alamogordo (even "in town") for people to have antique farm implements on display in their front yards. We didn't want to do that (we have a different motif in the front yard), but Carla has been keen to have a farm implement in the back yard. We had in mind perhaps a nice "walk behind" horse-drawn plow.

But, as a result of a chain of curious circumstances, we have just completed negotiations with the owner of a presently-defunct antique shop out on the westbound US highway to Las Cruces to acquire a quite elaborate ca. 1920-vintage Oliver No. 23-B "sulky" plow.

In that kind of plow, the operator rides it like a cart, it being drawn by two or three draft horses.

But that requires either that plowing be done in a "spiral" pattern for the whole field, or if parallel rows are wanted, the plow has to "deadhead" from the end of each row back to the starting side of the field so it can start the next row in the same direction.

In a reversible plow, there are two bottoms (that refers to the entire earth cutting and turning tool assembly), and at the end of one pass, the plow and horses are turned around, and the operator raises the bottom just used and lowers the other one, which turns the earth in the other direction.

We are now arranging to have the machine hauled from there to our back yard. (It is estimated to weigh over 400 pounds.)

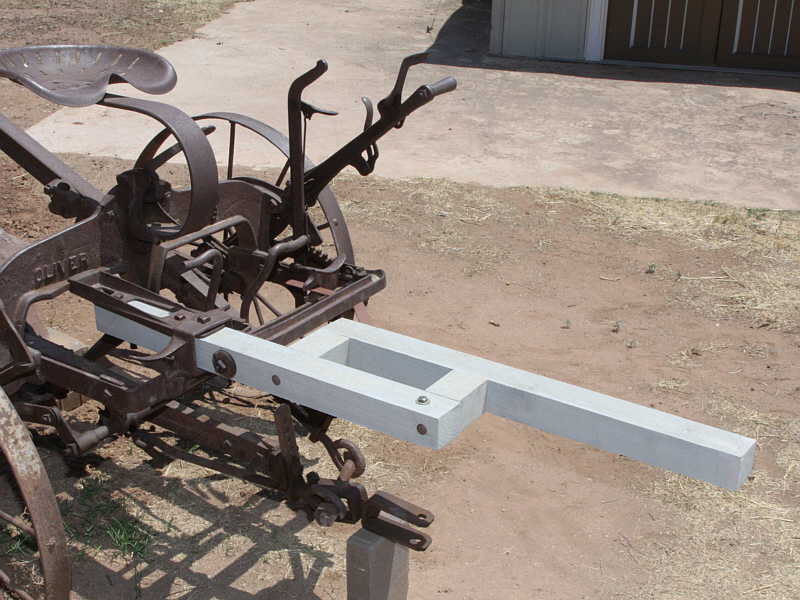

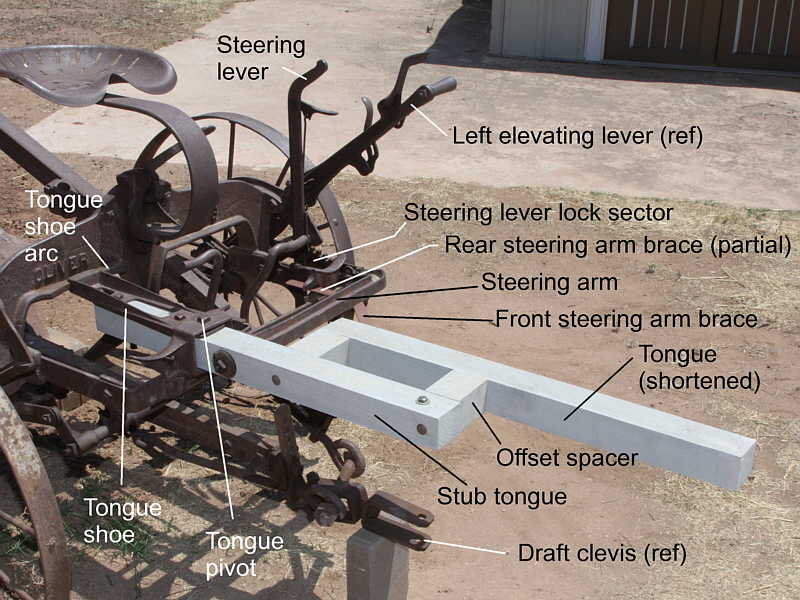

Here we see the machine of interest, in repose under the sign of the antique shop. Its front is to the left.

Douglas A. Kerr: Oliver 23-B sulky plow in retirement

You can see to the right the two separate bottoms, here both in the "raised" position, but since the plow is not coupled to any horses - in fact, its wood "tongue" is gone - it has rocked backward so both bottoms are resting on the ground. (You can see that from the attitude of the seat).

I'll tell you more about the machine and the operation of its many mechanisms a little later. It is a marvel of mechanical engineering.

In the meantime, this link is to a video of a fellow (a plow rebuilding specialist, in fact) plowing a field with an Oliver No. 23-A, an earlier version without quite such refined mechanisms.

http://www.youtube.com/watch?v=--WDmrbNUfs

Best regards,

Doug

But, as a result of a chain of curious circumstances, we have just completed negotiations with the owner of a presently-defunct antique shop out on the westbound US highway to Las Cruces to acquire a quite elaborate ca. 1920-vintage Oliver No. 23-B "sulky" plow.

In that kind of plow, the operator rides it like a cart, it being drawn by two or three draft horses.

As I'm sure you know, "sulky" normally refers to a light two-wheeled cart drawn by a single horse, such as are used in "harness racing" events.

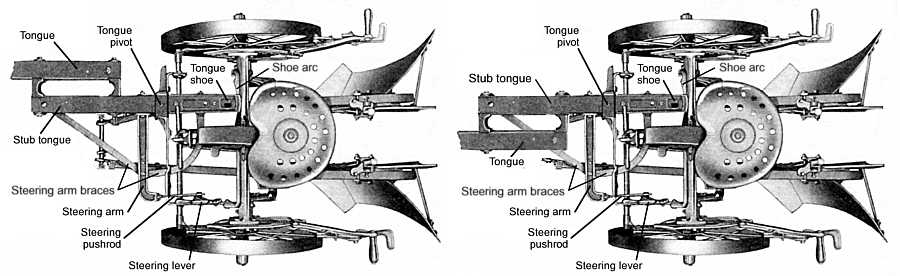

This is a reversible plow. In normal plowing of a field, all rows are turned to the same direction, so the earth turned over by one "pass" will fall into the furrow created by the previous pass. And of course a basic plow is made to turn the earth to one side or the other (most commonly, in the US, to the right, but you could order them either way).But that requires either that plowing be done in a "spiral" pattern for the whole field, or if parallel rows are wanted, the plow has to "deadhead" from the end of each row back to the starting side of the field so it can start the next row in the same direction.

In a reversible plow, there are two bottoms (that refers to the entire earth cutting and turning tool assembly), and at the end of one pass, the plow and horses are turned around, and the operator raises the bottom just used and lowers the other one, which turns the earth in the other direction.

We are now arranging to have the machine hauled from there to our back yard. (It is estimated to weigh over 400 pounds.)

Here we see the machine of interest, in repose under the sign of the antique shop. Its front is to the left.

Douglas A. Kerr: Oliver 23-B sulky plow in retirement

You can see to the right the two separate bottoms, here both in the "raised" position, but since the plow is not coupled to any horses - in fact, its wood "tongue" is gone - it has rocked backward so both bottoms are resting on the ground. (You can see that from the attitude of the seat).

I'll tell you more about the machine and the operation of its many mechanisms a little later. It is a marvel of mechanical engineering.

In the meantime, this link is to a video of a fellow (a plow rebuilding specialist, in fact) plowing a field with an Oliver No. 23-A, an earlier version without quite such refined mechanisms.

http://www.youtube.com/watch?v=--WDmrbNUfs

Best regards,

Doug